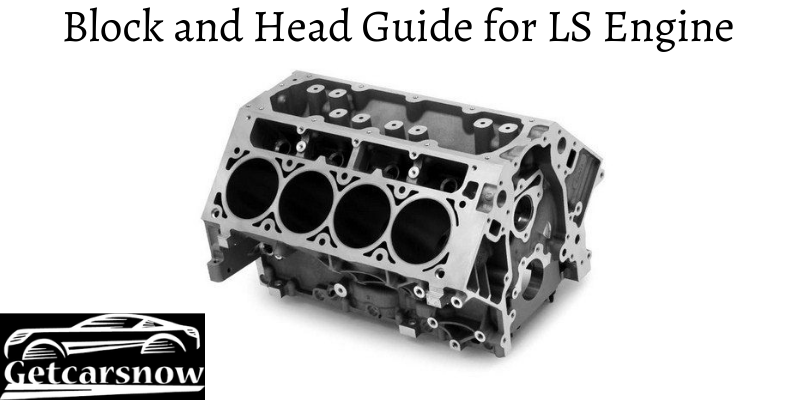

Block and Head Guide for LS Engine

There was a time when engines were assembled by hand. The engineers fitted many parts by hand even the block and head of engines. But then time changed and to save production money and time and to gain profit, the work of machines increased. The same happened with the LS Engines, but still, if you want to swap your engines with the old LS engines then, this is definitely tiring work. If you’re looking for an LS V8 engine to buy, here’s the guide. While swapping there is a part that can totally spin your head and that is Block and head. Here’s the block and head guide for LS Engine, because of course, we don’t want your head to spin.

Although many changes have taken place in more than fifty years, the one thing that never changed in both generations is that they remain attached to their roots. The LS remained 2-valve V8, pushrod engines. The epic part is that the distance between the centreline of each cylinder or bore centres has not changed since 1955.

Here’s the block and head guide for LS Engine.

First, let’s know what is an engine block/cylinder block? So Engine block/ cylinder block is the support to multiple engine parts. It consists of a water jacket to prevent engine heating and it also gives lubrication to other parts too. Nowadays engine blocks even support the gearbox. In modern automotive engines, the gearbox is bolted with the block.

There are two types of engine blocks present in the market. They are Monoblock Cylinder Block: In-line cylinder, V-Cylinder and the other are Individual Cylinder.

The work of the cylinder head is to create a combustion chamber at the top of the cylinder head. The types of engine head are SOHC(Single overhead camshaft) Cylinder head which has 2 valves/cylinder and the other is DOHC(Double overhead camshaft) Cylinder head which has 4 valves/cylinder.

Both the generations of LS Engine have a number of differences between them. But still, they follow the same traits. Now let’s read about the block and head guide for LS Engine.

Generation III LS Engine

When the first Generation III LS engine launched with the C5 Corvette in 1997. This engine gained so much popularity in so little time. And the one reason behind that is because it was the first Chevrolet Production all aluminium small-block V8. In generation 1 iron block, due to iron block it has 50 pounds much weight which results in performance reduction.

At first, the LS engines were focused on producing engines for trucks and heavy-duty applications. The attention of the engineers was only to the high performance and huge power numbers. As a result, the engines had lashed with iron blocks and aluminium heads. All engines were the same but there was one exceptional engine. The early 1998-’99 LQ4 engines has fitted with iron heads. But by 2000, all engines started using aluminium heads.

LS1 engine had quickly replaced by LS6 because of the increased cam timing and compression in LS6.

The rectangle cylinder port head has launched in LS3 which has the displacement of 6.2L. This change started a major shift in LS engine building. The predecessor engine of LS3 was LS2 which had displacement of 6.0L and 4.00 inches of bore, with all-aluminium blocks and cathedral port heads.

But this wasn’t the biggest breakthrough. The biggest breakthrough for the generation III LS engine block took place in the 2006 Corvette. LS7 has launched with 7.0L (427ci) engine.

This was the largest displacement change in the LS family engine history. This engine became the largest displacement engine in the LS family. This engine has the 4.125-inch bore and a 4.00-inch stroke.

Generation IV LS Engine Block and Head

When the LS engines were evolving from Generation III to Generation IV LS engine family then there has made many changes. While evolving to Generation IV, Chevrolet increased the size of their base engines, from 6.0L LS2 to an even larger 6.2L LS3 Generation IV engine.

While Generation III used a 24x wheel, Generation IV transformed themselves to a 58x (60 teeth minus 2) reluctor wheel on the crankshaft. As a result of larger tooth count, they upgraded to the more powerful E38 ECU.

It is very easy for you to identify the difference between Gen III and Gen IV blocks whether it is iron or aluminium. There is a cam sensor located at the top, behind the lifter galley cover. In both engines, the crank sensor is located at the same spot. So how come you know the difference? Well, there is a slight change in the colour of the sensor. The colour of the Gen III sensor is black and the colour of the Gen IV version is grey.

Generation IV was the first time LS piston squirters were first produced. It has used on the 427ci LS7 but after that, this engine has also been used on the supercharged LS9 Corvette engine.

Engine block and cylinder head material

Cast iron and aluminium alloy is used to produce blocks and heads. But both of them have a number of dissimilarities.

- The aluminium alloy block & head are light in weight and have high thermal efficiency. Whereas the cast-iron block and heads have comparatively heavyweight and low thermal efficiency.

- The aluminium alloy has lower strength at high temperature and a low compression ratio when compared to the cast-iron block.

- The aluminium alloy is suitable for gasoline engines while cast iron head and block are only made for heavy trucks.

- The failure of threads is higher in aluminium alloy compared to cast iron.

- The aluminium alloy is less corrosive but the cast-iron block and heads are highly corrosive.

- In aluminium alloy, the leakage in coolant damages the cylinder block and heads but in cast iron, there’s a system of high resistance to overheating of the engine.

It is very important to know about the materials of blocks and heads. Because if you lack knowledge in them then you may end up lacking your engine. There are many other things that come in do’s and don’ts while buying a used LS engine. Thank you for reading this article, we hope that it’ll help you with the information you are looking for.