Used 5.7 Hemi Engines: Know About Detail Parts & features

Hemi is a traditional trademark that represents high-quality engines for sale. These motor engines are hemispherical combustion by Chrysler. But when you are looking to buy a new one Hemi engines price is very high. So buying used 5.7 Hemi engines is always a wise & affordable decision for your motor.

A Hemi engine is usually, but not always, a cylinder with a domed head (instead of the traditional flat head) and a hemispherical combustion chamber. This setup can provide more power than conventional engines for higher compression ratios.

But before choosing used Hemi engines for sale, you need to understand a few basic but important points.

Here in this article, we will discuss used 5.7 Hemi engines parts detail and various features of Hemi engines for sale.

What makes used 5.7 Hemi engines unique- feature & benefits

The Hemi has a super-efficient combustion chamber, which makes it more powerful than other engines. Unlike a flat head piston on the engine, you can find it in your lawnmower. The Hemi piston typically has a dome-shaped head with open, angled valves and twin spark plugs per cylinder.

This configuration allows for,

- Excessive air intake

- An optimal mixture of fuel and air

- High compression

- High power output

Hemi engines typically burn all the gases in the cylinder, tapping all the potential energy. The Hemi angle crankshaft fully extracted with high compression & more combustion which provide high heat results. Also, a very little amount of energy generated in the combustion chamber. So the air & fuel subsequently pushing the exhaust.

Since heat helps to create pressure in the cylinder walls, heat preservation is important. Hemi design conserves heat through its unique shape. Also, the size of surface area relative to the size of its combustion chamber. Recall from high school biology that surface area, such as your skin, is one of the ways to dissipate heat.

Feature of used 5.7 Hemi engines

In an engine, if the size and shape of the head are larger than the size of the combustion chamber. The larger surface area of the head loses more heat than it generates the chamber. Loss of amount of heat for loss of energy. The fuel inside the chamber burns to release energy. If there is no large surface area of the head that loses heat, the fuel will never burn and not release energy.

The Hemi head surface area is much smaller than the traditional flat-head engine. Hemi loses less heat, allows higher pressures, higher heat, and more fuel combustion. The Hemi design employs angled valves on both sides. Previous designs placed the valves in a single-file line, limiting the possible size of each valve. With valves on either side, the valves have more room to grow. Hemi valves are much bigger than inline valves. Thanks to this large size, the Hemi valve exits on the flow of airflow through the engine.

Chrysler’s original design included provisions for a “multiple displacement system” (MDS). So the main oil galleries were injected & supply oil directly to the solenoid. That disabled lifters and oil rockers for lifters Used to come down.

Perhaps this is why the MDS system has been so successful and hassle-free in these used engines. But the original block was not designed to include variable valve timing (VVT) that was the next step in technology. So redesigning Chrysler Was lying. Block to update engine in ’09. The crank sensor for the VVT motor has 58 notches instead of 32 notches that were used on the original engine which was NGC.

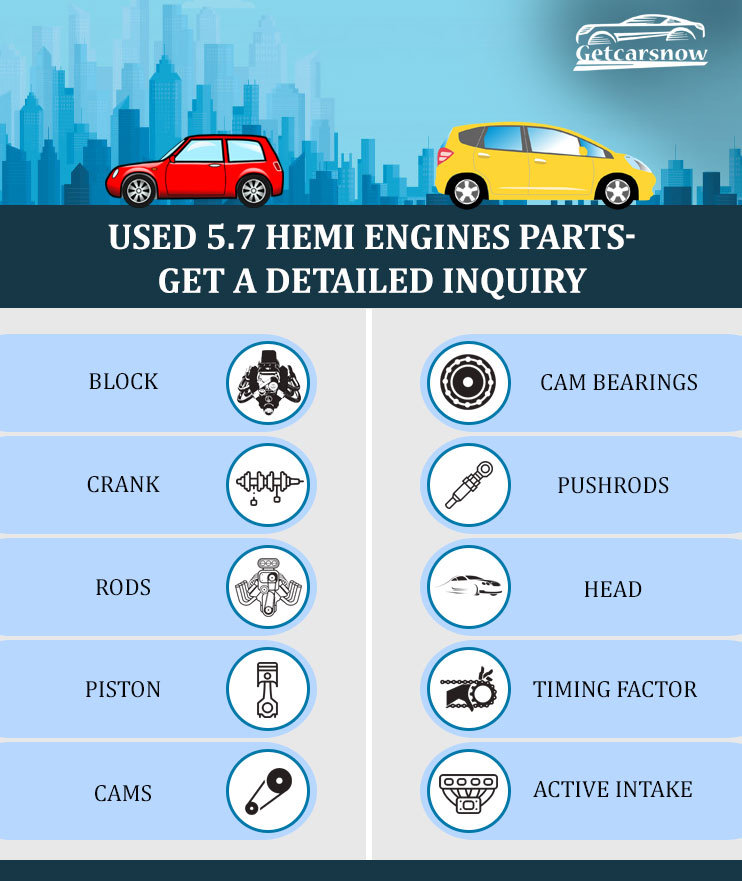

Used 5.7 Hemi Engines Parts- Get a detailed inquiry

The parts of any car or other motor engines are the most considerable & important things when you buy a used engine. Also, the same thing you need to apply when you looking for used 5.7 Hemi engines. The proper knowledge & understanding will give you the best & affordable deals on engines.

Block

A new block is required to connect the VVT to the HVI engine with three additional oil. This will passage and an extended front cam bearing which allows them to supply oil to the cam phaser through the front journal. The front of the block above the mains was progressed. This change allowed them to add an oil passage that would allow the main oil gallery to control the oil. Connected to the valve that directed oil to the phaser through the front cam journal. The cam bore for the front journal was increased by about 0.180 and was about 0.550.

Crank

The VVT motor takes place with a new Crime 53021300BB casting and it is still built of cast iron. But according to Chrysler, this much stronger and most noticeable difference from the original design is the length of the tapered area in front of the main magazine that makes the move and which detects the muzzle crimped. It was raised to around 0.460 But the line would be closed with a cam gear. That was modified for the block to proceed.

Rods

Powdered metal, lattice rods were redesigned to make them stronger. But they look like the early ones, except for a slight difference in the balance pad at the larger end. However, we believe that they are more robust as the VVT motors make more horsepower and torque and that the original rods in the General III motors were a weaker link, so they were definitely due to the upgrade. We would not recommend using early rods in late motors.

Piston

The original Gen III pistons were modified to accommodate a new. Narrow ring pack that had 1.20 / 1.20 / 2.0 mm rings instead of the 1.50 / 1.50 / 3.0 mm rings that were used through 2008. Other than that, it appears. Exactly the same piston which also has the same identification number inside the skirt.

CAMS

This is where it is interesting because there are five applications. That all share the VIN code “T”, even though they are all different and they actually use five different cams that are not interchangeable. The cams are unique to MDS motors because four of the consumption lobes have a “primary ramp” that closes the “locking lash” in the MDS lifter to the check ball in the lifter before the “secondary ramp”, and lay hold of four MDS exhausts in time. The lobes were advanced to some degree.

CAM Bearings

These engines require a wider bearing set. Thich consists of two slots located directly above the groove in the cam journal. Also, the number three bearing is coated with Babat, “reducing friction at the critical point on the cam Coated to. That improves durability during cold operation. ”Dura-Bond provides a bearing set for these engines.

pushrods

The pedestals for the rocker shaft were raised by about 0.200, as the top of the head casting was moved up to make room for the new “D-shape” exhaust ports, so the posh dresses are about 0.150 “longer”. This means the valves are longer, too.

Head

VVT Motors came with a new head that included several notable changes. We suspect that the Hemi chamber did not provide enough extinguishing and squish, even with “squish shelves” on both sides, so Chrysler probably had to go to the oval chamber to complete the emission.

Timing Factor

All timing components were modified, including gears, chains, tensioners, and guides. Cam gear is an integral part of the cam phasor so it is not available separately.

The crank gear has 23 teeth instead of the 26 found on the old gears. The distance between the links takes from center-to-center on the pins is longer. So there will be 76 links instead of the new chain. Also, there are 86 links found on the old links and it is about 0.100 ”narrower.

The color links on the original chain are replaced with 3 lasers attach to rectangles. On this link, we can measure the timing of the gear. The front cover includes a cam-thrust plate as well as a blade-style tensioner. Also, a chain guide is separated by three pieces with a separate cam thrust plate, a plastic chain guide, and spring-loaded pistons.

Active Intake

Although the active intake is not included with the long block. You need to know that the vehicle has one before selling the engine as it requires a special cam to work with the active intake. Also, you cannot rely on VIN codes to identify which engines have them because Chrysler calls them all VIN “T”, even if there are five different ones. You can find the VIN information with the help of the VIN decoder.

Chrysler installed the “Active Intake Manifold”, which extends the length of the intake runner to extend the torque and horsepower range on the engine. When it activates, the butterflies in the intake runners open at 4,000 RPM to create an intake path for a longer period of time, so the engine makes an extra 25 horsepower without losing any torque and ends up with 390 horsepower. You can really feel the difference when the short runner valve turns into my pickup truck.

These are the basic but very important part of used 5.7 Hemi engines you need to check before buying a used one. The proper knowledge & understanding of used engines or other parts such as used transmission for sale will give the best buying opportunity.

Summary

5.7 Hemi engines are more popular & the best choice for your car & other motors. Its high-quality performance & long duration service makes them an affordable choice as compared to other engines.

Here in this blog, we are sharing the information on used 5.7 Hemi engine parts inspection & features of these used engines. Complete understanding & information about the used 5.7 Hemi engine parts will be offering the opportunity to choose the best engines for a motor according to the requirement.

I hope this article will help you in getting the best deal on used 5.7 Hemi engines along with the proper knowledge. To get more information on different brands of used transmission for sale, you can click on the link.